How to manage the rapidly growing demand for a wide variety of product labels?

In Lithuania, product label printing is becoming a "hot" topic today. Why? There are several reasons for this:

- growing volumes and directions of export of goods;

- different requirements of different countries for product labeling and label information;

- various standards of international organizations and requirements for information provided together with goods.

It should also be appreciated that the requirements of states and international organizations are not constant. As an example, it can be mentioned that starting from December 2014, food product labels in the European Union will have to list all allergens included in the product composition. This means that the design and size of the labels will change, and a different list of allergens will be printed for each product.

How to manage a situation in which, on the one hand, the nomenclature and quantities of goods are increasing and, on the other hand, the variety of marking requirements is growing?

Companies in Lithuania face problems of managing label printing processes and are looking for various solutions. Let's try to define the origin of the problem, managed resources and possible solutions.

The problem consists of several components:

- The first is the resources needed for printing labels;

- The second - possible losses due to errors in the labels;

- Well, the third is the costs of process support.

Losses due to errors in labels are specific fines or additional logistics costs when the label does not meet the customer's requirements. In our experience, some customers focus on errors in the labels, such as incorrect expiration dates or batch numbers, when solving problems with label printing.

Process maintenance costs . This should include all IT costs for the operation of available hardware and software, as well as infrastructure, as well as other costs not directly related to the printing process, such as text translation, style editing, label image preparation and approval, or the like.

Label printing process . An example from practice. I had to communicate with one distribution company that prints large quantities of labels for its products. Hundreds of different labels with different data. The employee's computer has several hundred catalogs in which she finds the necessary label design before printing, then generates the texts and prints the required amount of labels. No one else can do this without her. In fact, her entire job is to print labels. I tell her about the possibilities to simplify this complex activity, I say that any employee will be able to print labels without additional training. I get a very straightforward and simple question: "Then what will I do here if everyone can print labels themselves?".

So, on the one hand - time is wasted adding the necessary texts to previously printed labels, on the other hand - the employee creates a mechanism, with the help of which he becomes irreplaceable. If we were to talk only about the time spent by the employee, we can safely say that half of the time required for printing labels is taken up by placing texts, reviewing the result, and correcting errors.

What are the possible solutions and how should they be assessed?

Don't change anything

Maybe you don't have many different labels, you work for the domestic market, the product label in most cases does not have variable information - that's all good. Well, there is one more error, but it is enough to review the process itself, adjust it, introduce an additional check and everything will be fine. In fact, installing additional software often results not because the program does everything perfectly, but because it forces you to work according to a strictly defined order. If you can introduce order through organizational methods - great. In terms of the three components of the problem, reducing the number of errors is not worth the increase in process maintenance costs due to shortening the printing process.

" After eliminating the number of errors, it is not worth increasing the costs of maintaining the processes due to the shortening of the printing process"

"The number of errors and the duration of the printing process are reduced, but the costs of maintaining the processes increase"

Use existing software

Whether it is a business management system (ERP), warehouse management system (WMS), or production - all of them have data storage and printing functionality. All of them work with lists of items or products, and they store various attributes of the items. So, label texts could also be stored there. It remains to contact the system developers and negotiate with them to adapt the user interface for text input.

Next is the label design. It's a bit more complicated here. You will have to contact the installers again and talk to them to prepare the required number of label options. You will have to accept the fact that design possibilities will be very limited - the main purpose of ERP or WMS is not to create label designs. But if the text variety of the labels is relatively small, if the texts are of similar volume - everything should be in order. Almost the most important condition is that the design of the labels should change as little as possible in the future, because every time you will have to contact the installers and pay money for the smallest change.

Evaluating the three components of the problem reduces the number of errors and the duration of the printing process, but increases the costs of maintaining the processes.

Look for a specialised label printing system.

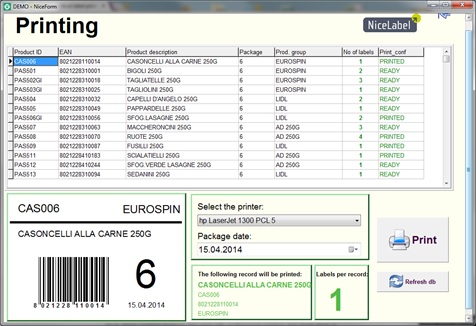

Such systems allow you to flexibly connect existing texts with label design fields, give company employees the opportunity to easily change the label design or create new labels, conveniently select data for printing and view the result on the computer screen. Such systems are available on the market, and they are relatively inexpensive. It is worth looking into the possibilities of label printing systems if:

- due to the large variety of labels, it is more convenient to manage the process of creating and adjusting labels yourself;

- the label design is complex, with graphic elements, variable font sizes, etc.;

- if you need to print dynamic information on the labels (expiry date, batch no., color, etc.);

- label data must be collected from several different management systems;

- there are many places to print labels and even in several countries - maybe it's worth thinking about an online printing system that would significantly reduce operating costs.

By implementing the third option, we reduce the number of errors and the duration of the printing process and optimize support costs. It should be noted here that due to the large variety of printed labels and their frequent changes, indirect costs should also be assessed when looking for the most suitable solution - meeting the customer's needs, reaction time to changes in requirements, etc.

Whichever option you choose, you will have to start with the analysis of printed labels. This is probably the most time-consuming job, especially if the labels are very diverse and numerous. It is necessary to fully clarify and systematize the labels, to establish internal rules for the preparation of labels.

" We reduce the number of errors and the duration of the printing process and optimize support costs "

Where to start?

Starting with the simple things:

- how many different size labels do you use? What are the options to reduce this number?

- is the data in the label only static or also dynamic? For example, expiry date, batch number, color etc

- how many different label types do you use? For example, the same for shoes, different for coats, different again for nail polish.

- how many different text fields in labels? For example, manufacturer, composition, country of origin, batch number, weight, EAN barcode, etc.

- is this data stored in one of the management systems you use, or does it need to be planned for its entry and storage as well?

- Are there new products coming out often that may require changes to the labels?

- does the employee who prints the labels need the preview function of the label before printing?

Let's say the answer to all the questions is "little" or "no" - then the first option is enough for you. If you answered yes to the last two questions, you should look for a specialized label printing system. In other cases, you will have to look for an optimal option, perhaps using ERP capabilities for entering and storing texts, and leaving the printing process itself and label design to the means of printing systems.

So what are the conclusions?

The preparation and printing of labels often becomes "business critical" for the company and it is necessary to pay attention to label printing systems. What are the main requirements for such systems?

- Reliability . If I'm printing labels, I need them here and now. Without labels, the product cannot be presented to the customer - this means unfulfilled agreements, customer dissatisfaction and other similar inconveniences.

- Flexibility . You never know what will happen tomorrow - you can only predict. New product marking requirements, new markets, new product models - you have to adapt every day.

- Configuration options . System parameters must be changed without additional programming work.

- Customization . It is the ability to configure the system to meet both today's and tomorrow's requirements.

- integration with various systems . Data required for labels is usually stored in the databases of other business management systems, so integration with them should be as simple as possible, configurable, not requiring additional changes in business management systems.